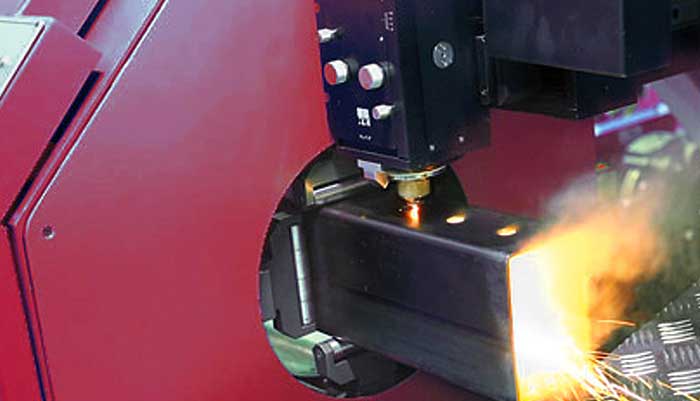

Tube Laser Cutting Systems 994

You don't need to coordinate multiple orders with different vendors. Gulf States Saw & Machinery Co., Inc. is able to handle all aspects of material procurement and delivery.

Fiber lasers cut in thin material with fast speeds. They also require little maintenance and are low in power consumption. This laser cutting technology's special properties allow applications in steel and stainless steel as well aluminum and non-ferrous metallics like copper or brass.